Catalyst Reclamation Systems

EnviroAir Catalyst Reclamation Systems are used to remove moisture, carbon, and volatile organic compounds from spent catalyst material before the process of separating precious metals from the carrier material takes place. EnviroAir will also provide the required air quality control equipment to ensure compliance with EPA and local air quality control standards.

EnviroAir Catalyst Reclamations Systems Feature:

- Indirectly heated – no flame impingement on spent catalyst to cause oxidation of the precious metals

- Exhausts are collected and discharged directly into air quality system – reducing pollutants

- Fully automatic system – simple to operate

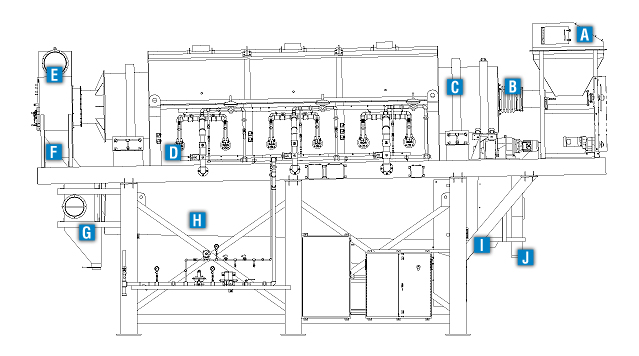

Catalyst Reclamation Process Diagram

Spent catalyst is fed into the input hopper.

Sealed screw feeder feeds the spent catalyst into the rotary retort at a constant rate.

Spent catalyst is heated to 1,600 to 1,700°F inside the rotary retort evaporating moisture, oxidizing carbon and volatile organic compounds from the spent catalyst.

Gas-fired burners heat the retort from the outside. This indirect heat prevents flame impingement on the spent catalyst that could cause oxidation of the precious metals being reclaimed.

Retort exhaust gases are collected in the retort exhaust hood and discharged to an air quality control system.

Transfer Chute

Cooling air is collected in the cooling drum exhaust hood and discharged to an air quality control system.

Heat from the reclaimed catalyst is transferred to the cooling air in the rotary cooling drum. The reclaimed catalyst leaves the cooling drum at no more than 30°F above ambient temperature.

Fines in the reclaimed catalyst are filtered through screened openings in the rotary cooling drum.

Reclaimed catalyst is discharged from the cooling drum and collected for further processing.

- Spent catalyst is fed into the input hopper.

- Sealed screw feeder feeds the spent catalyst into the rotary retort at a constant rate.

- Spent catalyst is heated to 1,600 to 1,700°F inside the rotary retort evaporating moisture, oxidizing carbon and volatile organic compounds from the spent catalyst.

- Gas-fired burners heat the retort from the outside. This indirect heat prevents flame impingement on the spent catalyst that could cause oxidation of the precious metals being reclaimed.

- Retort exhaust gases are collected in the retort exhaust hood and discharged to an air quality control system.

- Transfer Chute

- Cooling air is collected in the cooling drum exhaust hood and discharged to an air quality control system.

- Heat from the reclaimed catalyst is transferred to the cooling air in the rotary cooling drum. The reclaimed catalyst leaves the cooling drum at no more than 30°F above ambient temperature.

- Fines in the reclaimed catalyst are filtered through screened openings in the rotary cooling drum.

- Reclaimed catalyst is discharged from the cooling drum and collected for further processing.

AVAILABLE COMPLEMENTARY SYSTEMS

Air Quality Control System

EnviroAir can furnish a complete air quality control system for your catalyst reclamation furnace to ensure compliance with all EPA and local air quality control standards.

A typical pollution control system will include:

- Cyclone for removing large particulate

- High temperature baghouse for removing fine particulate

- Packed bed scrubber for acid gas removal if halogenated or sulfur bearing compounds are expected in the spent catalyst

- Water quench for cooling the exhaust gases prior to the packed bed scrubber

Carbon and volatile organic compounds found in the spent catalyst are normally destroyed in the rotary retort furnace. An external thermal oxidizer is not required to achieve air quality compliance in most applications. EnviroAir may provide an external thermal oxidizer to ensure compliance depending on the expected contaminants on the spent catalyst.

Material Handling Equipment

EnviroAir can furnish the material handling equipment needed to transport the catalyst material to and from the rotary retort furnace, including hoppers, conveyors, bucket elevators, vibratory screen separators, barrel dumping stations, etc.